Implementing technology, delivering value

MMR Group MediaTransfer (formerly TTM Technologia

Transferu Mediów) is a leading supplier of original and customised products and services

on the Polish liquid, gas, or solid utilities’ transmission market.

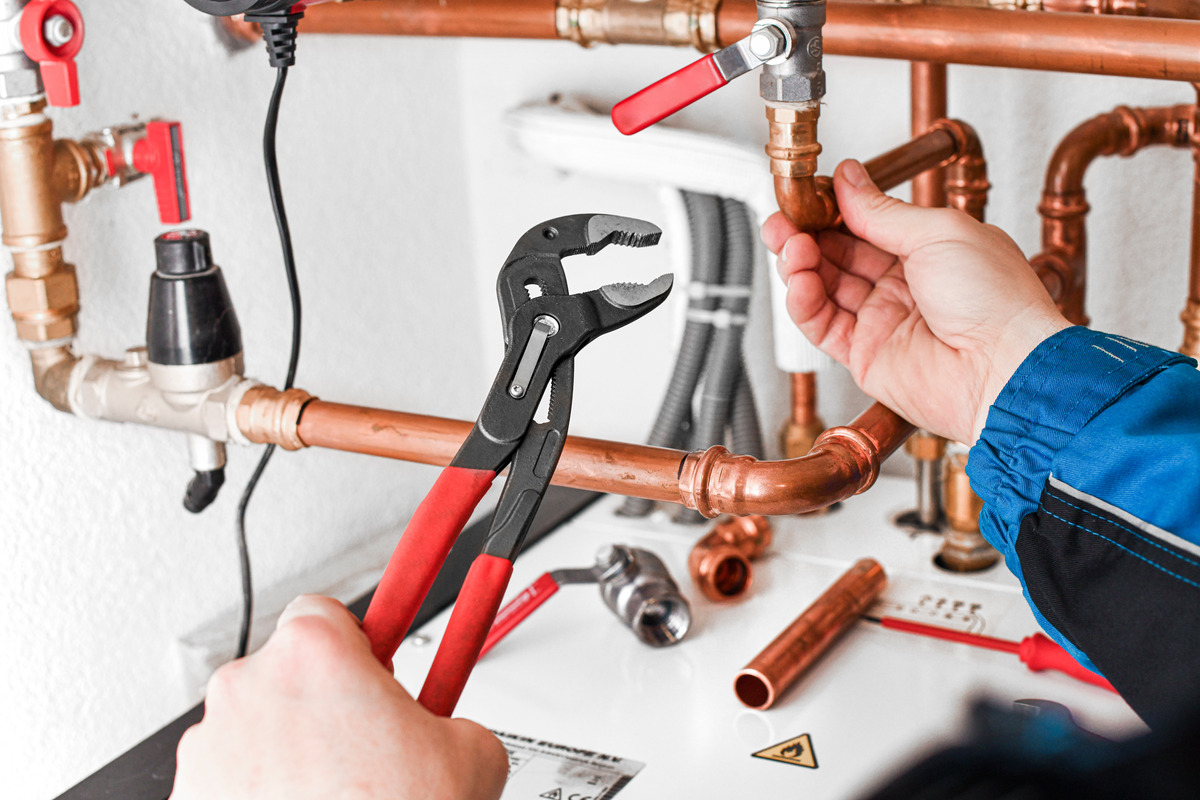

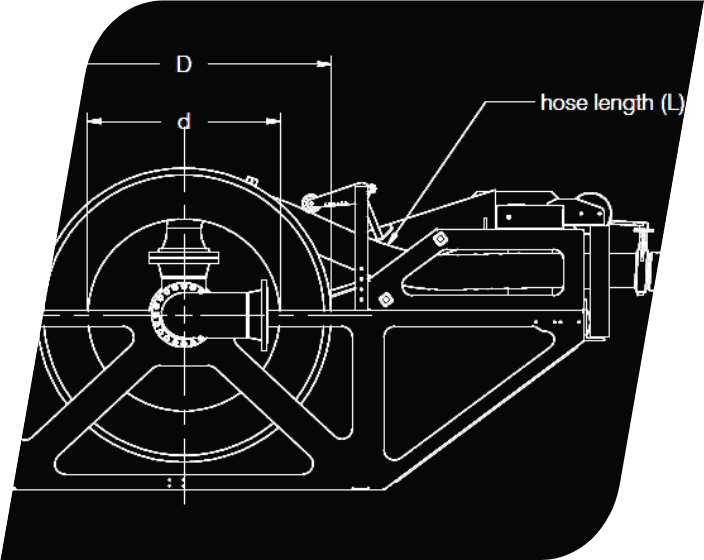

Our Products

Services

Thanks to long-term experience on the market and sector-specific know-how, MMR Group MediaTransfer delivers comprehensive services - from the production of industrial hoses, through design, to installation/assembly and maintenance of NO (Filling and Emptying) equipment and industrial plants.

Industrial hose packing and labeling, pressure and tightness testing, periodic testing

Design, appraisal, installation and acceptance supervision of NO equipment

Preparation of technical and registration documentation and communication with all required Technical Supervision Authorities

Service of NO equipment from all manufacturers

Inspections and periodic examinations, modernizations, overhauls

Supervision welding of pipelines and others

Advisory services

and training

The MMR Group

We provide customised and tailor-made product and service solutions for the industrial and printing sectors on the Polish market.

We plan, design, and implement a diverse range of certified product and service solutions of the highest quality. With each of them, we provide our Customers with value-added in the form of economic benefits, functional, long-term and safe exploitation, constant modernisation following state-of-the-art technology, as well as in the form of achievement of goals set for us by the sustainable development concept.

News

28.05.2025

MMR Group MediaTransfer at H2POLAND & Net Zero Forum 2025

On April 8-10, 2025 in Poznań, MMR Group MediaTransfer participated in the H2POLAND & Net Zero Forum 2025 event – the first conference and exhibition event in Poland and Central and Eastern Europe dedicated to energy and decarbonization of the industry.

28.05.2025

Invest in savings! Conti® Thermo Protect high temperature insulation system

For one of its clients, a leading manufacturer of specialist tyres, MMR Group MediaTransfer conducted a cost simulation of a project to insulate a vulcanising press for tyre production, powered by saturated steam at a temperature of 160°C, using the Conti® Thermo Protect system. As a result, heat energy losses were significantly reduced, and the estimated return on investment (ROI) time, at current rates for electricity used to produce steam, was approx. 5 months.

06.11.2021

Maintenance-free monitoring of conveyor belts

Interview with Marek Rochlitzki, President of M&MR Trading Polska Sp. z o.o., published..