The NO (filling and emptying) device is a technical solution for the safe loading and unloading of solid, liquid or gaseous substances from railroad tank cars, tanker trucks, storage tanks or process plants.

According to Regulation of the Minister of Transport*, each NO device is subject to the supervision of the Transport Technical Supervision Authority (TDT), and, in the case of military systems – the Military Technical Supervision Authority (WDT).

NO devices include, among others:

- loading arms (offshore, onshore – top, side, bottom)

- flexible hose devices

- couplings, valves, compensators and emergency systems

- control and automation systems

MMR Group MediaTransfer is licensed by the Technical Transport Supervision Authority and the Military Technical Supervision Authority to design, manufacture and upgrade NO equipment, completing projects from concept to acceptance with an inspector.

* Journal of Laws of 2006 No. 180 item 1321

With engineering competence and knowledge of technical supervision procedures, MMR Group MediaTransfer guides the client through the entire implementation process - saving the client’s time, eliminating design risk and ensuring the operational readiness of the device.

Stages of cooperation with MMR Group MediaTransfer:

- 1. Analysis of technical and process requirements.

- 2. Technology selection and development of the concept for the solution.

- 3. Technical design and preparation of documentation for the Technical Transport Supervision Authority.

- 4. Submission of documentation to the Technical Transport Supervision Authority for its approval.

- 5. Manufacture and prefabrication of the NO device.

- 6. Delivery, installation and integration with the client’s systems.

- 7. Final acceptance with the participation of a Technical Transport Supervision inspector.

MMR Group MediaTransfer is the official partner of JLA, a division of the J de Jonge Group, specializing in the production of marine arms for handling liquid and gaseous media. In developing its solutions, JLA relies on more than 35 years of service experience working with equipment from various manufacturers, which allows it to create exceptionally thoughtful, reliable and durable designs.

JLA arms are designed for specific terminal and medium requirements, taking into account operating conditions and the expected level of automation.

Depending on your needs, they can be equipped with:

- heated transfer sections (for high-viscosity or freezing products)

- cryogenic insulation – for such media as LNG, ethylene, liquid hydrogen, ammonia

- breakaway connectors (ERC) with ESD circuits

- compensators and safety valves

- position and pressure monitoring systems (HART, Profibus, etc.)

- automatic parking and locking systems

- full integration with terminal control systems (DCS/SCADA)

The arms can be tailored to handle both seagoing vessels and smaller, coastal vessels or barges.

What distinguishes the JLA are:

- its ropeless balancing system – which eliminates cable wear problems and minimizes maintenance

- in-house production of swivel connectors – precise, low resistance, durable, easy to service

- fully electric, autonomous marine arms – no hydraulics needed, lower maintenance costs, remote control capability

- modular design for easy servicing and upgrading

- adaptable to work in redundant or sequential systems (multi-arm systems)

JLA is the future of marine cargo handling systems – designed by practitioners, built for operators.

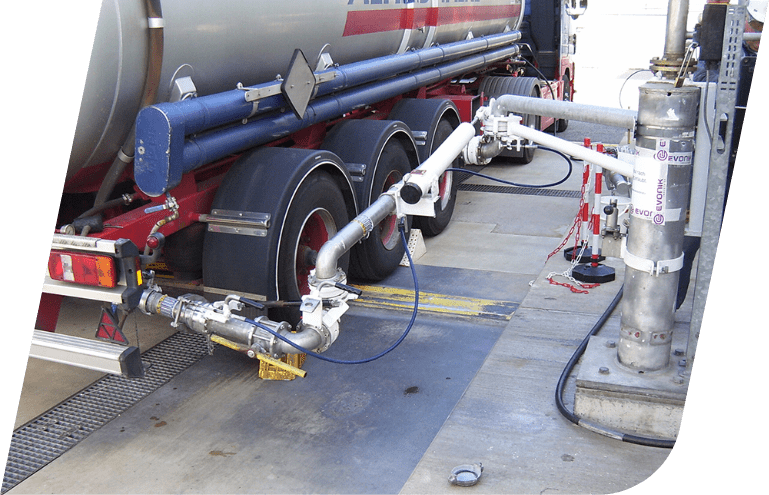

For onshore applications, MMR Group MediaTransfer offers solutions developed by WLT Liquid & Gas Loading Technology, a manufacturer of onshore handling arms for a wide range of media (from LPG to acids and oil). The arms are designed on the basis of many years of engineering experience in the area of aggressive media, always based on the needs of a specific application - without using ready-made templates.

Arm types by handling method:

- top – for loading/unloading road and rail tank cars from the top

- bottom – dedicated to LPG, fuels, H₂, cryogens

- side and special – for custom applications or confined spaces

Advantages of WLT arms:

- extremely durable low-friction swivel joints

- tightness and resistance to aggressive media (acids, bases, alcohols, LPG)

- very accurate and clear technical documentation

- customizable lengths, work directions and relief mechanisms

- integration with automation systems, according to the requirements of the Technical Transport Supervision Authority

WLT arms are “tailored” solutions, created to perform reliably in the most demanding environments.

At MMR Group MediaTransfer’s division in Kostrzyn near Poznan, we manufacture NO hose equipment tailored to work with fuels, chemicals, technical gases, cryogens and hydrogen. Our designs are based on components from reputable suppliers:

- Novaflex

- Continental

- Thor

- RS Components

MMR Group is licensed by the Technical Transport Supervision Authority and the Military Technical Supervision Authority to manufacture and upgrade NO equipment, ensuring full regulatory compliance and quick serviceability.

Configurations and components:

- breakaway connectors (ERC)

- dry-disconnect couplings

- hoses in composite, steel, PTFE, rubber versions

- fittings in stainless, acid-resistant, aluminum versions

Design options:

- lattice support frame - protects the hose from ground friction, increasing its durability

- hanging on the hoist of a pole crane - for ergonomic handling of heavier hoses

- compatibility with existing controls and ESD

Hose equipment manufactured by MMR Group MediaTransfer has proved its top performance where flexibility, safety and quick availability matter.

We specialize in projects dedicated to such industries as:

- petrochemical: JET-A1 jet fuel, Pb95 gasoline, Diesel fuel, fuel oil, polyvinyl chloride, bitumen

- chemical: sulfuric acid, caustic soda, sodium hypochlorite

- fuel: LNG, LPG, ammonia, chloride, hydrogen

- food: ethylene